Products

PRODUCTS

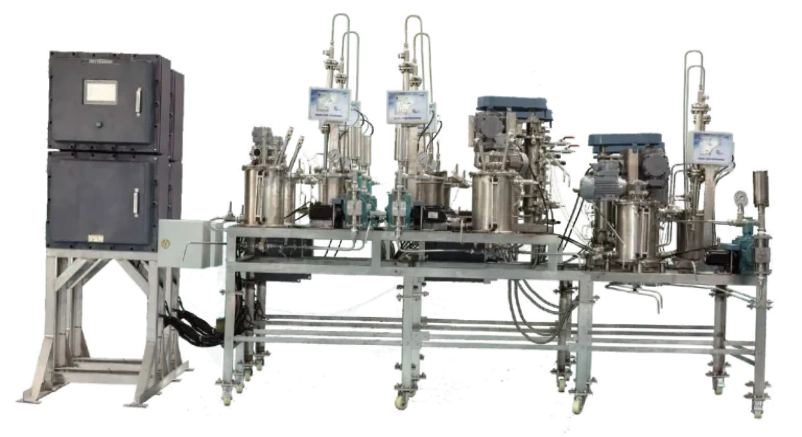

TWIN FLOW REACTOR

The Twin Flow Reactor System is specifically designed for multi-stage chemical reactions, where the output of

one reactor seamlessly transitions as input to the next reactor in a continuous series. Each reactor operates independently,

allowing precise control of reaction conditions, even when they differ across stages. This ensures a streamlined,

uninterrupted flow of the final product.

Reactants are pre-cooled or heated using inline heat transfer devices to rapidly achieve optimal reaction conditions, enhancing process efficiency. With superior control over variables like temperature, pressure, concentration, and mixing, the Twin Flow Reactor System delivers higher yields and consistent product quality, making it an ideal choice for multi-stage chemical processes.

Reactants are pre-cooled or heated using inline heat transfer devices to rapidly achieve optimal reaction conditions, enhancing process efficiency. With superior control over variables like temperature, pressure, concentration, and mixing, the Twin Flow Reactor System delivers higher yields and consistent product quality, making it an ideal choice for multi-stage chemical processes.

TWIN PLATE REACTOR ADVANTAGES

- High heat transfer area per unit reactor volume.

- Rapid mass transfer with increased interfacial area.

- Minimal interaction between reacted, unreacted, and semi reacted material.

- Enhanced safety, accommodating very high pressures with reliability.

- Compact design requiring significantly less space.

- Reduced waste generation for improved yields.

- Simplified downstream processing.

- Superior energy efficiency for optimized operations.