Products

PRODUCTS

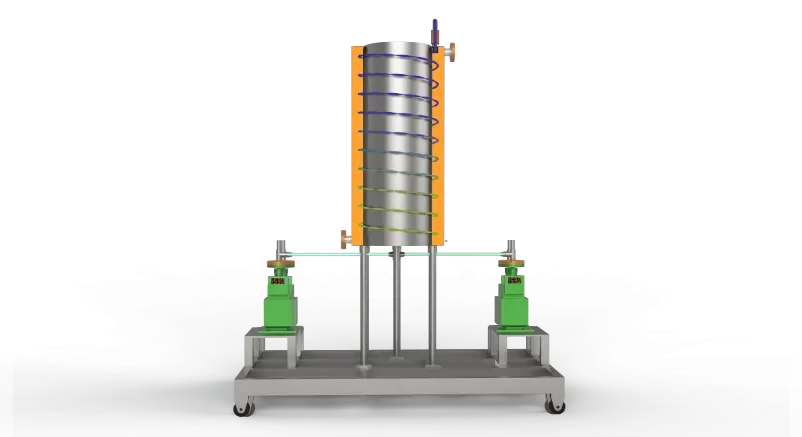

PINCHED TUBE

REACTOR

REACTOR

The Pinched Tube Reactor is specifically designed to optimize the mixing of reactants, such as liquids or slurries,

while maintaining plug flow for uniformity and efficiency. The reactor incorporates carefully engineered

constrictions within the flow passage at predetermined intervals, which generate the necessary turbulence

for efficient mixing while preventing backflow. This design ensures consistent and effective chemical reactions.

- Reactor Materials of Construction (MOC): Austenitic SS, Hastelloy, Inconel, Monel, Titanium, and other high-performance materials

- Heating/Cooling: Solenoid jacket for precise temperature control.

- Chemical Processes: Ideal for Nitration, Sulfonation, N-Alkylation, and Halogenation.

PINCHED TUBE REACTOR ADVANTAGES

- High heat transfer area per unit volume, achieving 500-1000 m²/m³.

- Low pumping energy requirements.

- Maintains plug flow, preventing mixing of reacted, unreacted, and semi-reacted materials.

- Easy scalability for process expansion.

- Capable of handling high-pressure reactions with assured safety.