Products

PRODUCTS

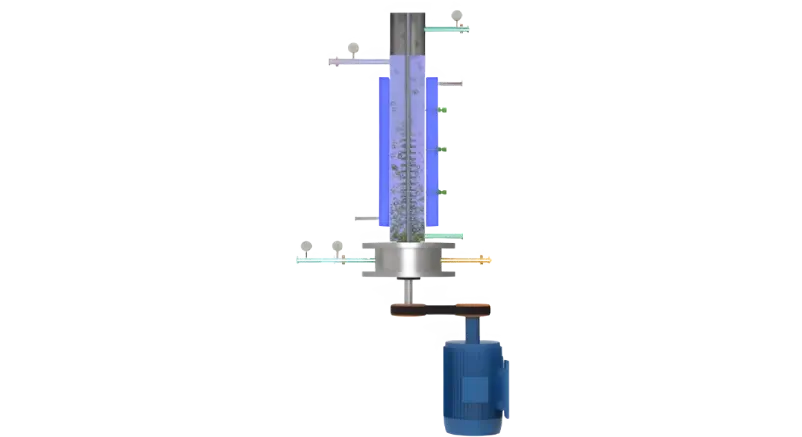

FLUIDIZED BED REACTOR

Hydrogenation and Ammonolysis Reactor

This reactor is ideally suited for hydrogenation and ammonolysis processes. It is constructed with high quality materials such as Austenitic Stainless Steel, Hastelloy, Inconel, and Monel to ensure durability and performance.

- Reactor Materials of Construction (MOC): Austenitic Stainless Steel, Hastelloy, Inconel, Monel, and more.

- Heating/Cooling Options: Limpet/External Jacket with optional heating/cooling from the shaft.

- Chemical Processes: Hydrogenation and reactions involving gas introduction or production during the reaction.

FLUIDIZED BED REACTOR ADVANTAGES

- Efficiently handles liquids and slurries.

- Reaction times range from seconds to hours.

- Superior mixing performance.

- Capable of high-pressure reactions up to 100 bar

- Heat transfer rates between 50-100 m²/m³.

- Flexible placement of additional feed, sampling, and sensing points along the axis.