Products

PRODUCTS

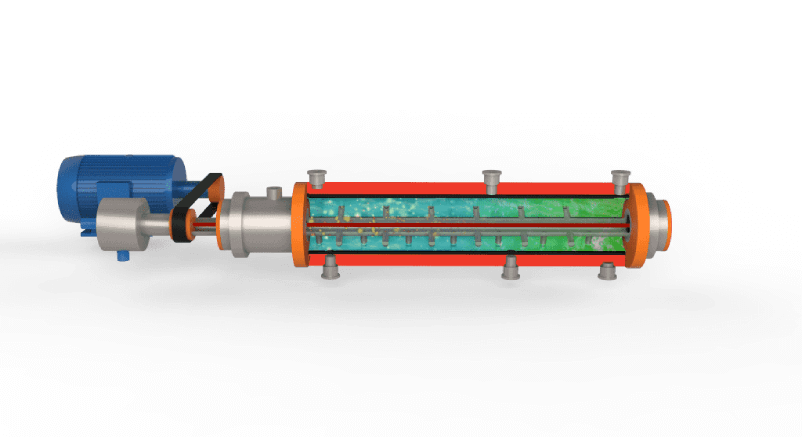

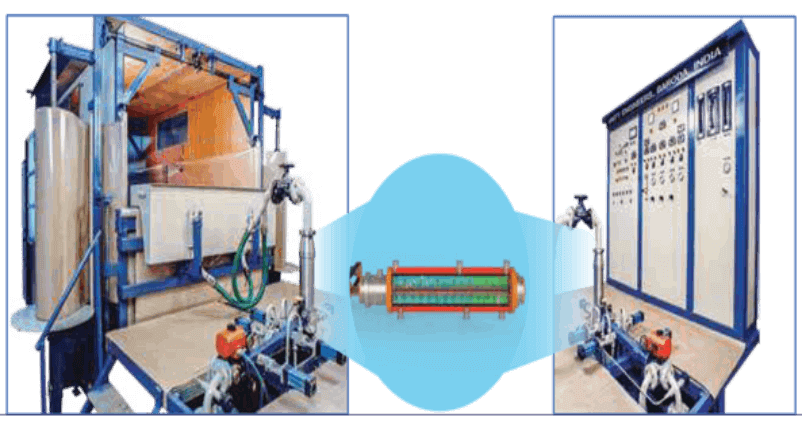

Continuous Stirred Tubular Reactor (cstur)

The CSTUR Reactor is designed for the precise manufacture of Flexible Polyurethane Foam.

It offers exceptional capabilities for accurately dosing up to 7 different liquids with

varying densities and viscosities, along with gas, to ensure precise chemical reactions.

This versatile system is applicable to a wide range of chemical processes.

- Reactor Materials of Construction (MOC): Austenitic Stainless Steel, Hastelloy, Inconel, Monel, and more.

- Heating/Cooling Options: Limpet/External Jacket with optional heating/cooling from the shaft.

- Chemical Processes: Halogenation and reactions involving gas production during the reaction.

CONTINUOUS STIRRED TUBULAR REACTOR ADVANTAGES

- Efficiently handles liquids and slurries.

- Reaction times range from seconds to hours.

- Superior mixing performance.

- High throughput capacity.

- Heat transfer rates between 50-100 m²/m³.

- Flexible placement of additional feed, sampling, and sensing points along the axis.

- Option to integrate catalyst packs within the flow line or along the reactor wall.