Products

PRODUCTS

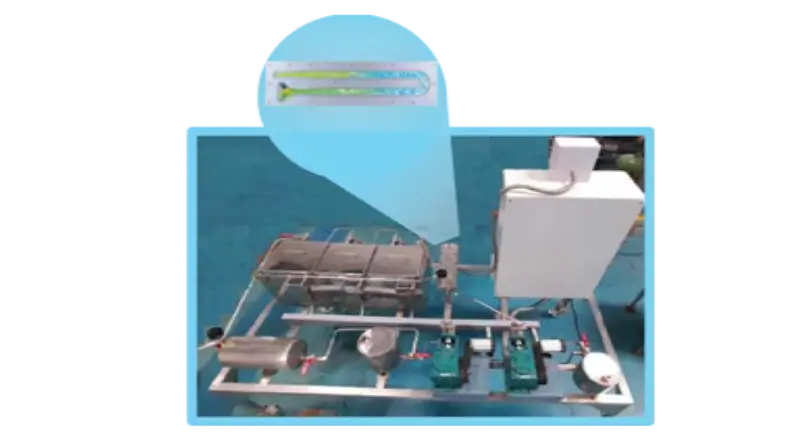

PLATE TYPE REACTOR

The Plate Type Reactor is designed to efficiently mix reactants, which enter through separate inlets and

converge into a single laminar flow. Strategic obstructions within the flow passages at defined intervals generate

the necessary turbulence for optimal mixing while maintaining plug flow and eliminating dead zones.

- Reactor Materials of Construction (MOC): Austenitic SS, Martensitic SS, Hastelloy, Inconel, Monel, Titanium, Filled PTFE, Borosilicate Glass (for photochemical reactions).

- Heating/Cooling: External jacket, ceramic heaters, and induction heating options for precise thermal management.

- Chemical Processes: Suitable for Sulfonation, Chlorination, Hydrogenation, Photo Halogenation, Nitration, Oxidation, Sulfoxidation, and more.

PLATE TYPE REACTOR ADVANTAGES

- Excellent heat transfer area of up to 2000 m²/m³.

- Flexible placement of feed, sampling, and sensing points within the matrix.

- Easy scalability for process expansion.

- Capable of supporting photochemical reactions.