Products

PRODUCTS

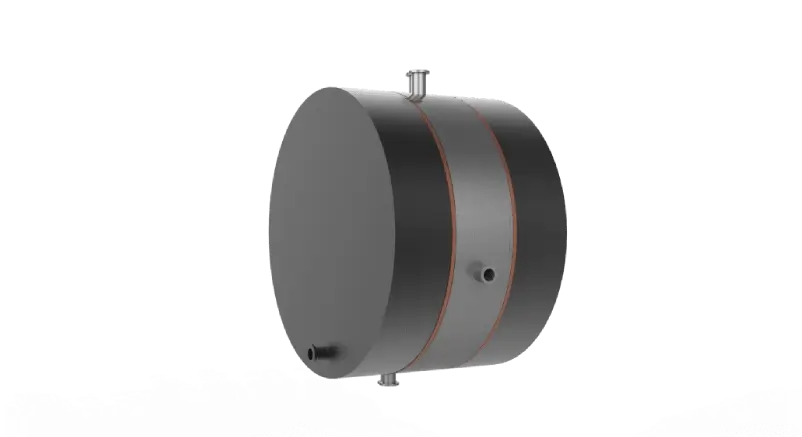

PIN MILL REACTOR

The Pin Mill Reactor is engineered to facilitate rapid chemical reactions with a high degree of flexibility,

making it suitable for both small-scale and high-volume production processes.

Its design ensures optimal performance across various reaction conditions, making it an

ideal choice for industries requiring efficient and scalable chemical processing.

- Reactor Materials of Construction (MOC): Austenitic SS, Martensitic SS, Hastelloy, Inconel, Monel, Glass, and more.

- Media Options: Ceramic, Hastelloy, SS, with optional catalyst-packed media.

- Heating/Cooling Options: Single/Double Side Jacket with an annular chamber

- Chemical Processes: Ideal for UV light reactions, Sulfonation, and Nitration.

PIN MILL REACTOR ADVANTAGES

- Efficiently handles liquids and slurries.

- Reaction times range from seconds to hours.

- Circular agitation for enhanced mixing efficiency.

- Option to integrate catalyst packs within the flow line and stirring media.

- No rotating seals required.

- Visual observation of the reaction process through glass windows.

- Heat transfer area ranging from 100-200 m²/m³